The customer - Bicoma - is an Italian manufacturer of automation machinery for use specifically in the stone field - cutting marble, stone, granite etc. Bicoma is proud to be one of the most innovative companies operating in this sector, and are globally renowned for their high quality machinery production.

IMO Automazione were approached by the customer who was looking for a dual solution for their Fast 2000 Diamond Wire Cutting Machines, which were using a variety of components from an assortment of manufacturers. The customer was looking to eradicate some technical issues they had experienced with their existing drives, whilst also looking to drive down their ever spiralling costs.

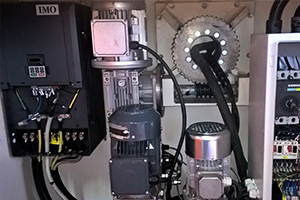

After careful evaluation, two SD1 drives were selected, based upon their ability to communicate with each other, their accuracy and incredible reliability, tested to the extreme as their working environment would be exceptionally challenging, and at high altitude in the Apuane Alps. The SD1-4.2A-21 (0.75kW) variable speed drive was selected to control the linear feed of the carriage. The SD1-115A-43 (55kW) variable speed drive was selected to control the cutting head speed. Using PID control, the speeds are matched to ensure the greatest efficiency of the cutting process, without breaking the cutting cable.

The installation of these two IMO SD1 drives has not only resolved the technical issue Bicoma were experiencing with previously used components, but has also dramatically reduced the individual component costs of the Fast 2000 Diamond Wire Cutting machine.

|  |

|

|

"

We have chosen the IMO products because they symbolise the Italian mentality and the mentality of the people from “Massa Carrara”. The products are easy to program, strong and offer optimum value for money. There are many companies that manufacture drives, but it is not easy finding a friend that helps you find a complete solution.".

"

We have chosen the IMO products because they symbolise the Italian mentality and the mentality of the people from “Massa Carrara”. The products are easy to program, strong and offer optimum value for money. There are many companies that manufacture drives, but it is not easy finding a friend that helps you find a complete solution.".

Lead Project Engineer, Bicoma

To meet the IMO drives range click here.